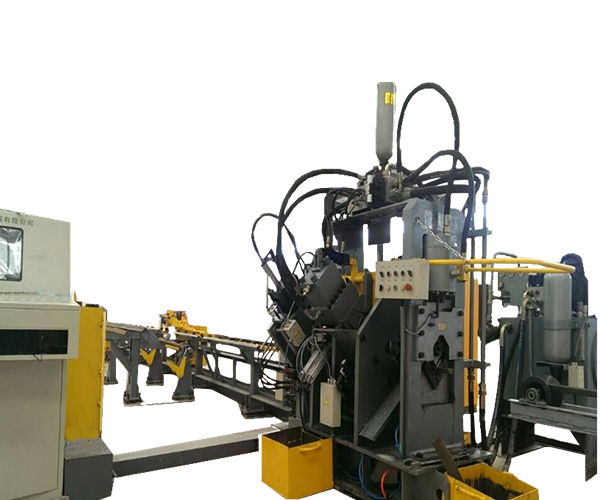

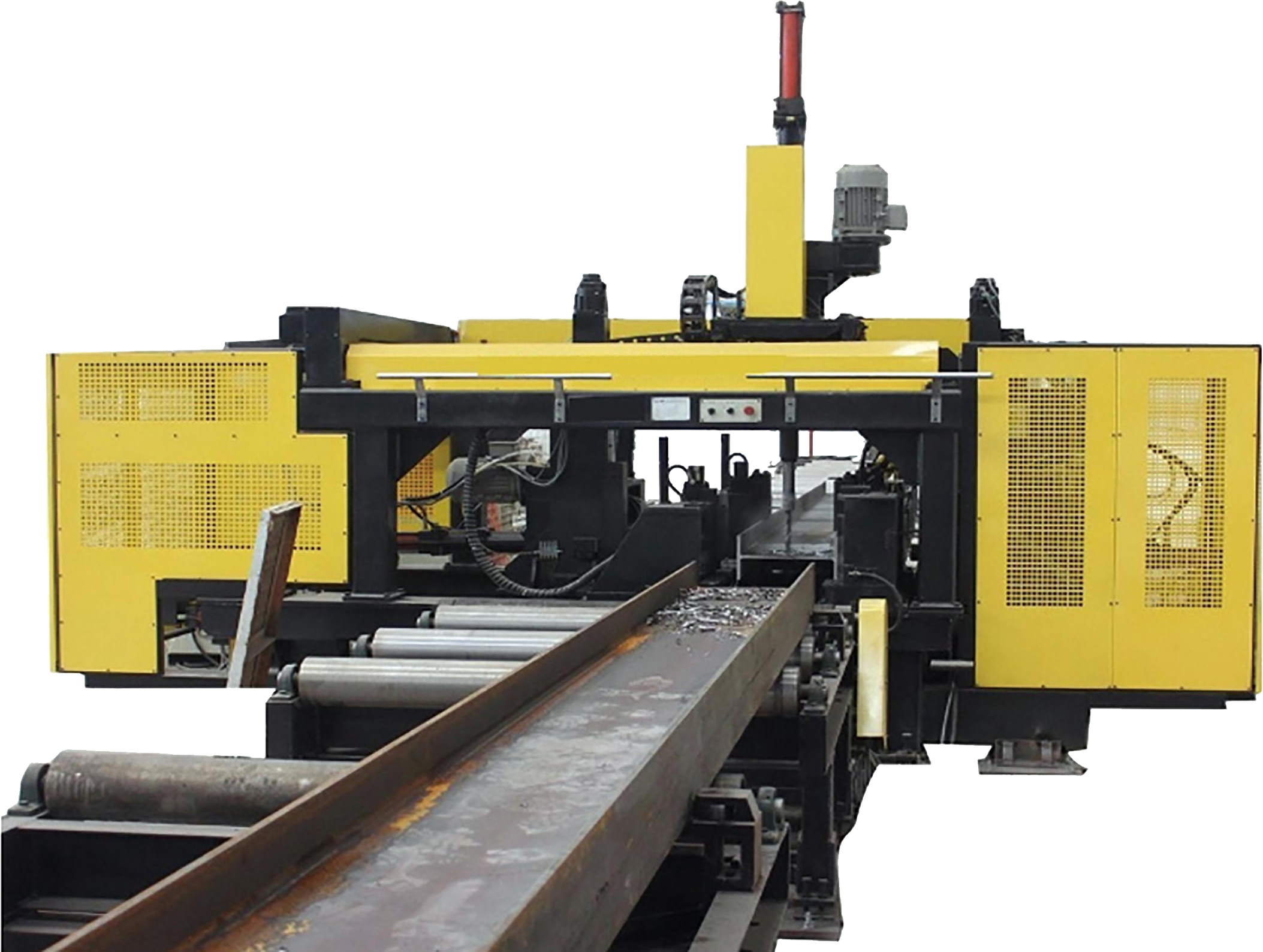

The machine is the automatic special equipment used for angle steel marking, punching, and shearing mainly in the field of angle steel tower industry.

High Speed CNC Angle Punching, Marking and Shearing Machine Line for Angle Steel Tower

Product composition:

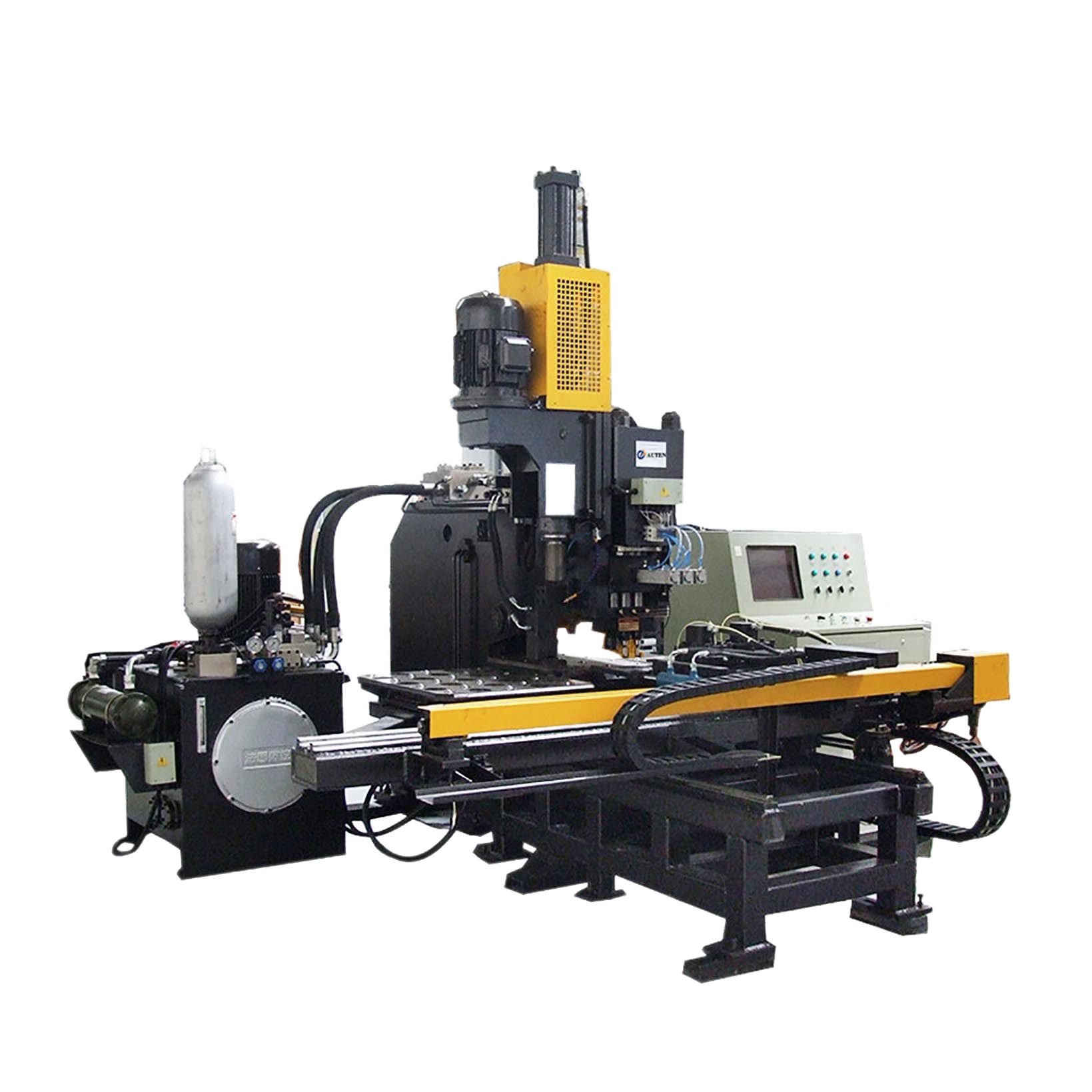

This machine is mainly composed of transverse conveyor, rotating loading system, infeed conveyor, CNC infeed carriage, punching unit, marking unit, cutting unit, unloading conveyor, as well as hydraulic, electrical and pneumatic systems etc.

Product Feature:

1. Feeding speed and punching speed are very fast. The speed is 3 times higher than previous common angle line machines. Greatly improve the production efficiency.

2. There are two sets of punching die-station on each side which can be installed two kinds of punches with different diameters.

3. Marking unit adopts closed frame with good rigidity. Four sets of character boxes are fixed on the marking unit which can be selected by program. Marking stadia can be set at will.

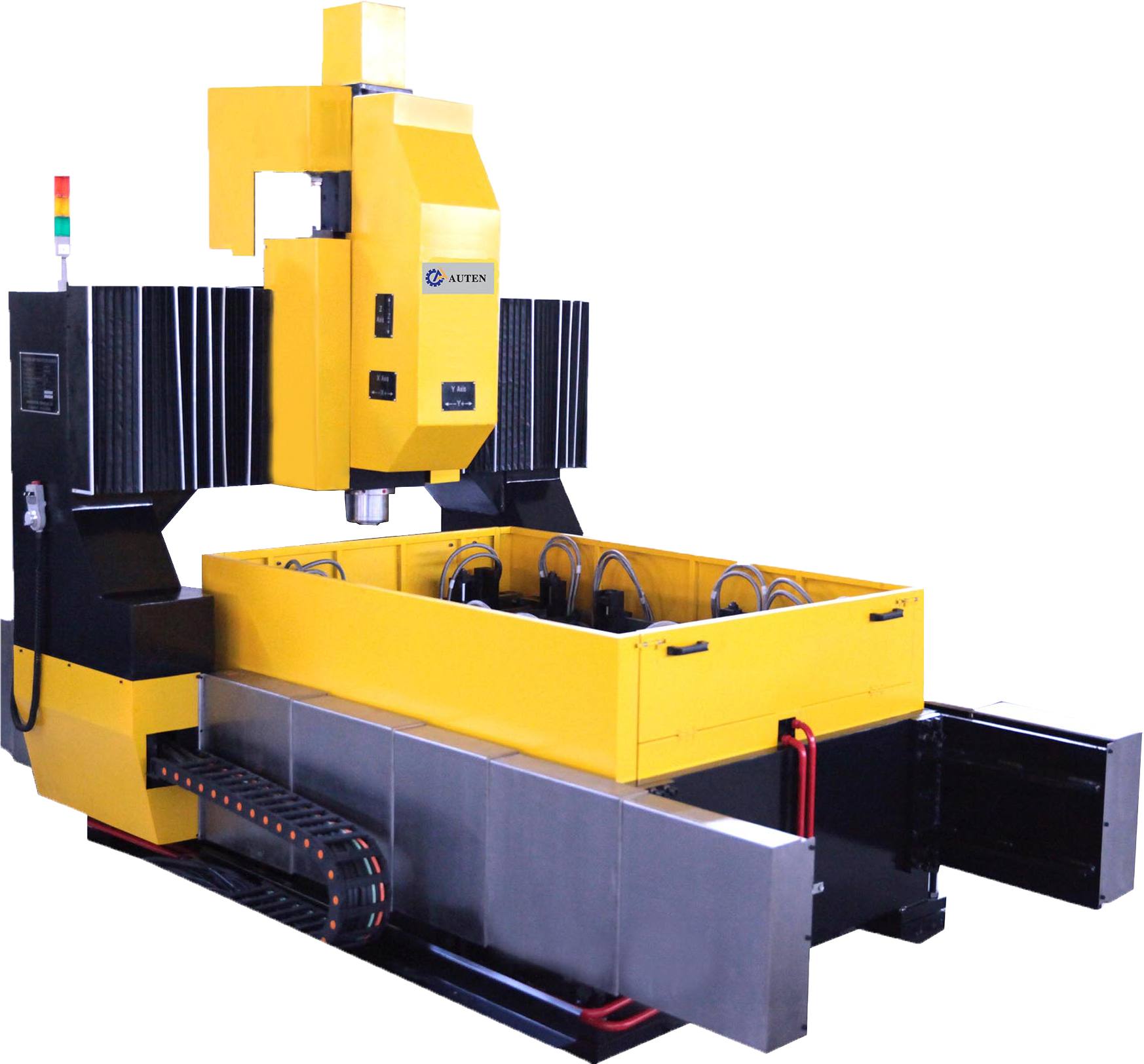

Adopt CNC technology, servo motor in feeding, with high efficiency, stable work piece precision. Key hydraulic, pneumatic and electric parts all imported.

4. Hydraulic system mainly serves for punching, cutting, marking, pressing and transposition of character boxes. All marking, punching and shearing in automatic completeness, all finished angles can be unloaded by pneumatic turnover device so as to lighten the working strength.

5. Control system consists of upper computer, CNC system, servo motor, PLC and outside detection switch etc. Processing program can be generated automatically as long as operator inputs the dimension of workpiece. It can also accept certain processing program which is made from special software. The program can be stored, selected, displayed and communicated as per the workpiece No..

6. X,A,B CNC axis are driven by imported brushless AC servo motors. The CNC system is controlled by imported PLC, which attached with three axis CNC modules. The modules and three axis servo system constitute a position control loop. The photoelectric encoder feeds back the information. Closed loop control to ensure high positioning precision.

7. Single blade shearing ensures smooth shearing section and save raw material. With function of self-diagnosis for failures.

Model | JNC125 |

Functions | Punching, marking, cutting |

Angle size(mm) | ∟40×40×3~∟125×125×10 |

Max. length of blank (m) | 12 |

Max. length of finished (m) | 10 |

Max. Punching (dia. х thi.) (mm) | Φ26×10(Material:Q345 510N/mm2) |

Max. Punching elliptical hole (dia. х thi.) (mm) | Ф22×50×8 (Material:Q345 510N/mm2) |

Punches per side | 2 |

Punching force (kN) | 630 |

Marking force (kN) | 630 |

Cutting force (kN) | 1000 |

Group of Marking letters | 4 |

Number of letters per group | 12 |

Dimension of letter (mm) | 14×10×19 |

Cutting mode | Single blade cutting |

CNC axes | 3 |

Feeding speed of angle (m/min) | 80 |

Cooling method of hydraulic system | Water cooling |

Processing precision | Accordance with GB2694 |

Program function | Input by keyboard and USB interface |

Dimension(mm) | 28000×6500×2200 |